JEMS Drag Bike

About the Owner

Jon Edwards of JEMS Race Engineering is best known for his work on high-performance race cars and racing engines. His career has seen him working in UK and Australian Touring cars, European GT racing, Knight Racing Services, the top V8 engine tuning company and Goodman building Metro 6R4 engines. Having establishing JEMS he has built some of the best YB engines produced for racing including some with over 1000bhp. His engineering and set up skills have seen him build some of the most competitive MK2 Escorts for racing and rallying and muck, much more.

So it may come as a surprise that Jon is now looking to go Drag Bike Racing. It is not actually as big a departure as it first seems. He had in fact once worked for a drag bike company for four years, early in his career, and had considered drag bike racing but chose car racing instead. The desire to go drag bike racing has always burnt inside and Jon is now building a Street Class bike on which to start this new chapter in his career.

Building the Bike

The Bike

The bike the project is being based on is a Suzuki GSX-R1000 K1 model from 2001. This was a groundbreaking and revolutionary motorcycle of its time and an excellent platform on which to build a competitive drag bike. The engine which was designed to be lightweight and revved quickly will be standard to start with. It will be controlled by a Motec ECU (Engine Control Unit) fitted and mapped by Dave Roe from EPS, a specialist in motorsport electronics.

Jon will, of course, use his incredible engineering knowledge to develop a bike as competitive as it can be. He will start with the street bike class called PRO ET. This uses a frame from a normal road bike but you can basically do what you chose for the rest of the bike.

The main modifications will be a longer swinging arm on the rear wheel, this helps to stop the front wheel from lifting off the track as you accelerate, and the clutch is very heavily modified. The clutch is a very complicated part of the setup as the RPM and load are made fully adjustable, essential for making the critical good start and again to stop the front wheel lifting off the track.

Although Jon is a leading engineer in the world of car racing and has some experience in drag bikes he understands the need for expert knowledge. To start his drag bike career as competitively as possible he is working with Webster Race Engineering on the build of his first bike. They are a specialist drag racing company based next to the Santa Pod Raceway in the UK. Working with a specialist will give the project a great starting point and reduce the time required for Jon to develop the bike into the best it can be.

Webster Race Engineering:

www.websterraceengineering.co.uk

EPS Motorsport (Dave Rowe):

www.epsmotorsport.com

The Suzuki drag bike during the dummy build.

Progress on the bike build

Trial fitting of the lowered dampers. These are used to get the bike as low as possible and keeping the center of gravity down. They also put rake on the bike which helps weight distribution and limits the front wheel from lifting on launch.

The bespoke build exhaust is checked for clearance.

Extended footrest have been designed and built for the bike. Extending the footrest enables the rider to lie down further on the bike and reduce drag.

The extended footrest on the other side of the bike.

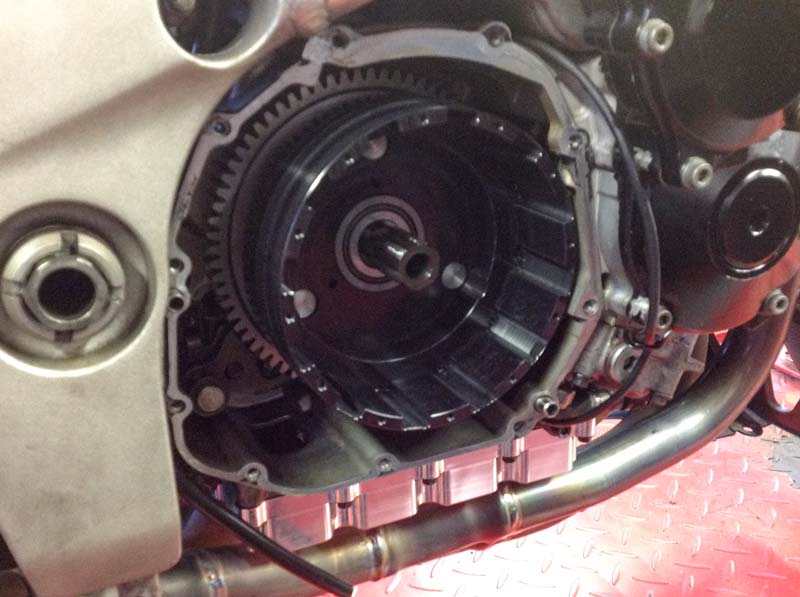

The most important part of the bike, this is a Hays drag race multi set up clutch.

The clutch cover prior to installation.

The clutch housing ready for the clutch.

The finished clutch installation.

The extended rear swinging arm fitted with lower ratio sprockets and a heavy duty chain.

This is a dummy build. The final build will take place when all our modifications are finished.

The lowered front end has now had the clearances checked.

This is the complete longer rear arm with the race specification chain and lower ratio gears.

Another view of the exhaust and repositioned footrest and brake.

The clutch cover over the Hays drag race multi set up clutch.

About Drag Racing

Jon will start his racing in the Norwegian championship, using the first year to develop his riding skills and tuning the bike as he learns more about it and what it takes to be competitive. After the initial development period, Jon will travel to Sweden to compete where there are larger events. He will also travel to the Santa Pod Raceway in the UK.

Jon's goal is to progress to the ultimate street class called Super Street. In this class, riders compete to be the quickest in the world on bikes that have over 600bhp.

Jon will be racing at the Gardermoen Raceway in Norway http://ndrg.no/

The PRO ET Class

The PRO ET uses a structure very common in drag racing and it enables many different bikes to race in one class. PRO ET caters for street bikes and pro drag bikes and the structure is know as a ‘dial in class’. It works by the competitors setting their own time that must be no quicker than 7.50 sec and no slower than 9.99 sec to cover the quarter mile course. The average top speed in this class is 150mph. On the runs the competitor has to cross the finish line as close to their dial in time as possible, if they go quicker they are disqualified.

For example, competitor number 1 could start with an 8.00 second dial in time, and the competitor, number 2, next to them on the track could start with a 9.00 second dial in time. When the starting lights go trough their sequence competitor number 2 would start 1 sec earlier and, in theory, both competitors should cross the finish line at the same time. The competitor that was closest to their dial in time is the winner (eg. If number 2’s time was 9.01 seconds and number 1’s was 8.02, number 2 would win).

As you can see from this website Jon Edwards and JEMS Race Engineering are highly talented, well respected and long established company. JEMS is a very professional, friendly and outgoing race team and would be a good ambassador for any sponsors brand.

As a sponsor you have the opportunity to align your message with our success. Display your leaflets in the race awning; your logo on team clothing, race trailer, race awning and on the motorbike itself. JEMS understand the value of recommendation and they would do so about your services to other drivers, race teams, fans and the media.

Your involvement with the team will be published on this website and across social media throughout the bikes build, development and success on the track.

Contact Jon on phone number (0047 95970860) or email trough this site for a meeting in person or on phone to discuss the possibilities and JEMS’ expectations.